|

|

|

|

|

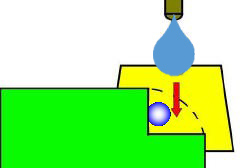

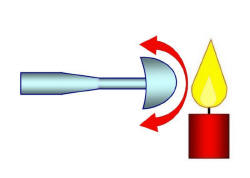

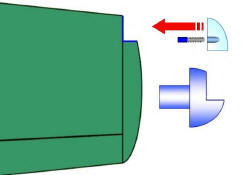

Heat clear plastic rod

(sprue from kit) over a candle; turn rod to get an even heating. |

| |

|

|

|

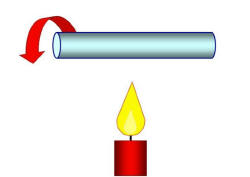

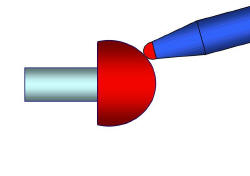

Remove from flame when

plastic gets soft (shines) and pull ends slowly apart to a thin rod (narrow

for a little light, thicker for a bigger one). |

| |

|

|

|

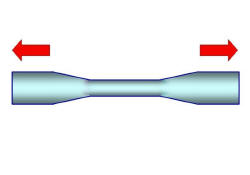

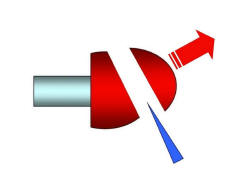

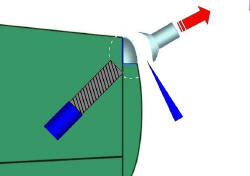

Cut in half; spare one end

for further use. |

| |

|

|

|

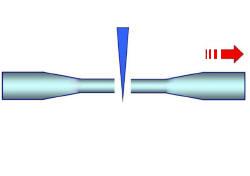

Put one end near a candle

flame (there should be no wind) until the end rolls back to a mushroom form.

Remove from flame. |

| |

|

|

|

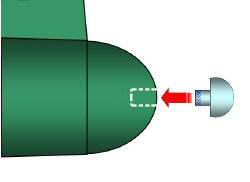

Slightly squeeze mushroom to get the horizontal planform into a teardrop shape. |

| |

|

|

|

Use transparent permanent marker to get

the

desired colour (red for an anti collision light in this case). |

| |

|

|

|

Cut diagonally as appropriate

to get the right shape. |

|

|

|

|

|

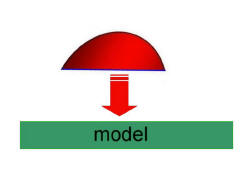

Apply glue to underside of

light and fix it onto model. Ready! |

|

Wing lights: |

|

|

Conventional way:

Remove appropriate part in kit wing.

Heat and press

clear sprue to tear drop shape as described above, If in the original a coloured light bulb is

covered by transparent glass, drill a hole and

colour it with permanent marker (blue right side, red left side) to resemble the light bulb.

Glue part in, sand and polish to

blend it in if necessary.

Alternative below: |

|

|

|

|

|

My favorite way, perfect fit

guaranteed: Heat and soften

one end of clear sprue, then press it into the precut aperture. Take care

that it is completely covered. If the

original position light is covered by tinted glass apply cement to insides

of the aperture before the clear sprue is pressed in (permanent fix).

If the light contains a coloured light

bulb covered with transparent glass, remove clear sprue, bore hole in the

appropriate place and colour it. Then glue clear part in (cement only to the

insides of the aperture!).

|

|

|

|

|

|

Cut off outer parts of the

clear sprue, sand remains to shape (as the outer parts of the clear part

should not have contact with the glue they should go off easily). Fine grade

sandpaper and polish is used in the last step to get a shiny appearance. |

|

Alternative, easy and safe: |

|

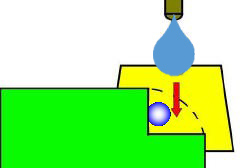

Remove light part, insert (scratch)

light bulb, cover cutout with flexible adhesive tape on one side, carefully fill

epoxy glue in (no bubbles!) ; if necessary trim front edge after glue has

hardened, then polish it. If there is some adhesive from the tape left it

can be easily removed with thinners; alternatively adhesive tape slightly

larger than the opening can be fixed on the lower tape, non sticking surface

upside. |

|

Other lights: |

|

|

Rear position light: As described

above, but leave some lenght of stump. Apply glue and insert part (colored

white) into

predrilled hole. |

|

|

|