|

Modelling-ABC by Wilfried Eck |

W

| Water: |

|

Chemical element, consisting of two atoms of hydrogen and one atom oxygen.

Reproducing water in model form is a difficult task. For ship models of 1/700 scale a pane of glass with a wavy surface painted blue-green on the underside may be sufficient, for larger scales I didn't find out a suitable material. Transparent polyester seems to be best, but as it produces heat during the hardening process it harms plastic or at least the paint. Silicone is also possible, but it is not as transparent as the descirption "transparent" makes one believe.

It's also not perfect, but "Fimo" seems best. Is a plasticine that can be moulded to a high degree and is hardened in the oven (you can even mould figures with it).

|

To produce a "water surface" I place as many strings of Fimo as are needed to cover the underlying cardboard or plywood panel side by side and merge them with pressure of my fingers until the surface is about even and smooth. Then I simply use my fingernails to make depressions (waves). Naturally you can take any rounded tool you like as well, as after this first step something with a rounded tip of smaller diameter is used to produce smaller waves.

If the ship is in motion it needs a bow wave and some equally wedge shaped ones behind as well as a distinct foaming stern wave at the rear. Bow and adjacent waves are formed as mentioned above, the stern wave needs a different treatment. For a foamy appearance I use a pencil to make little holes and a stiff brush to accentuate this further till an uneven spongy surface is obtained. Though Fimo can be painted to any desired color, it's not a bad idea to use some white Fimo for the bow wave and stern wave. Pressing the ship into the Fimo surface for a moment gives a clear indication where the waves have to begin (do not leave it in Fimo for a long time because unhardened Fimo melts plastic).

Whether you cut out the necessary opening to submerge the ship to the desired level before or after the hardening process depends on you.

Now put the whole assembly (without the ship!) into the preheated oven (175 degr. C) and let it harden for 20-30 minutes. As it's hot afterwards use of gloves is recommended. If a slight warping has occured, place it on an even surface, put something heavy on it with a towel or else between (this is not to say warping has to be expected) and wait for some time.

When everything is o.k. you can paint and highlight to your wishes with glossy paint. After this has thorougly dried at least one coat of glossy transparent laquer (i.e. "Future") should give this watery affair a convincing look.

Finally the ship is fixed with white glue.

Alternatives: 2-component transparent glue, transparent polyester (warning! gets hot during drying process).

Weathering of models (Ageing):

Whether weathering of a model is needed is mentioned elsewhere. In short: Detoriation of paint needs an adverse environment and time. Glossy paint is more resistant than a matt(e) one.

If a model really needs "ageing" it needs a subtle hand. Mostly it's grossly overdone. If not done perfectly forget about "weathering". Only very old residents of the junk yard showed significant traces of sun and heat. Modern carrier based aircraft are washed regularly, spots of different paint are leftovers from corrosion checks.

The best way in my opinion is the following:

Apply a thin layer of the desired paint and let dry.

Spray spots of lighter* (and/or darker) shades in appropriate places and let dry.

Overspray lightly with original colour.

* use yellow for greens and reds, light blue or blue gray for darker blues; white only for black or gray tones.

Advantage of this method: You can't overdo it. If the final paint coat is too thick it will cover the light/dark coloured areas.

Example: B-24 of page "Modellfotos 1".

Also see page A "ageing"

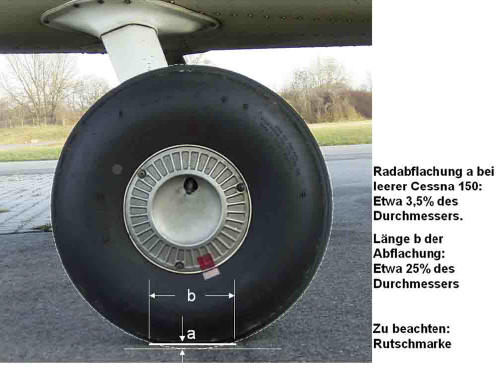

On land based aircraft wheels are part of the landing gear, pneumatic tires (tyres) also acting as damping device. The question is how much the tire of the wheel is flattened by weigth. The smaller the rubbing area is the less friction and drag it creates. An aircraft with half flat tires won't get off the ground because exzessive kneading creates heat causing the tire to blow. On the other side a stone hard tire won't fulfill its damping function. It's up to the manufacturers to find out which construction, rubber mixture and air pressure is ideal for a certain purpose. The high pressure tires found on carrier based aircraft will show very little flattening whereas huge low pressure tires for aircraft operating on soft ground will show much more. In the middle of these extremes a Cessna 150 light sports aircraft fits in:

|

Photo and

caption by Prof. Gerd Busse Translation: Flattening a of an empty Cessna 150: About 3,5 % of wheel diameter. Length b of flattening (Ed.: fully oaded condition): About 25 % of wheel diameter. Watch slip mark.

|

As told in item "landing gear" flattening of of tires is far less than modellers think. So it's quite sufficient to sand off a small portion if you're lucky enough to get circular wings. Otherwise the missing area has to be built up by putty.

Painting tires without painting the hubs as well isn't easy if the wheel is held stationary. It's far easier to turn them durch painting.

|

Take a toothpick or match or whatever fits into the central hole. Then I wet the inner tire area slightly with thinner. A small portion of the desired colour is also thinned a little bit. If this is brought near the hub with the brush held at an angle it will run around the hub for some distance. In some cases, it is helpful to use a needle or pointed tool to accentuate the outer edge of the hub beforehand. Repeat this procedure until a ring is obtained. Now fill in the rest with paint of normal consistence, turning the wheel. After the paint has dried on one side the procedure is repeated on the other one.

Dark gray colour is more realistic than pure black.